sheet metal drawing operation is used to make

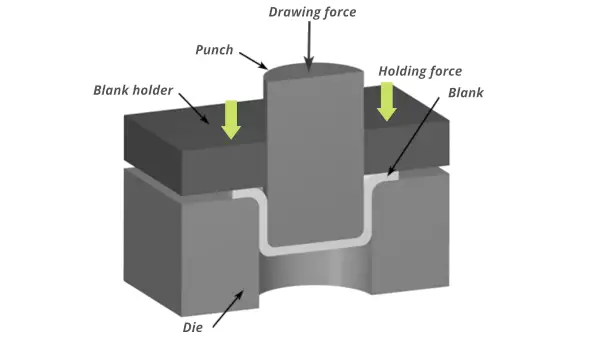

Sousa in Reference Module in Materials Science and Materials Engineering 2016 Abstract. Deep drawing of sheet metal is performed with a punch and die.

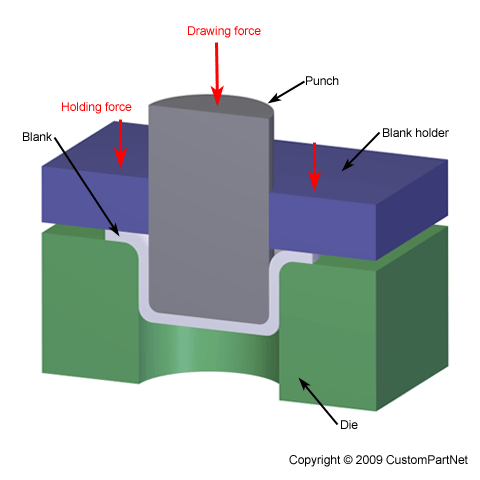

The method relies on a punch and die often made from a hard metal.

. Drawing is a metal forming process in which a product is made by controlling sheet metal flow into a cavity and over a punch. This will increase the strength and avoid the. In other words Piercing is a combination of cutting and forming.

Cutting and forming thin sheets of metal usually performed as cold working Sheet metal 04 164 to 6 mm 14in thick Plate stock 6 mm thick Advantage - High strength good. Piercing is a type of sheet metal punching operation used to create an extruded hole or slot in a sheet metal workpiece. Mainly sheet metal process can be divided into three types.

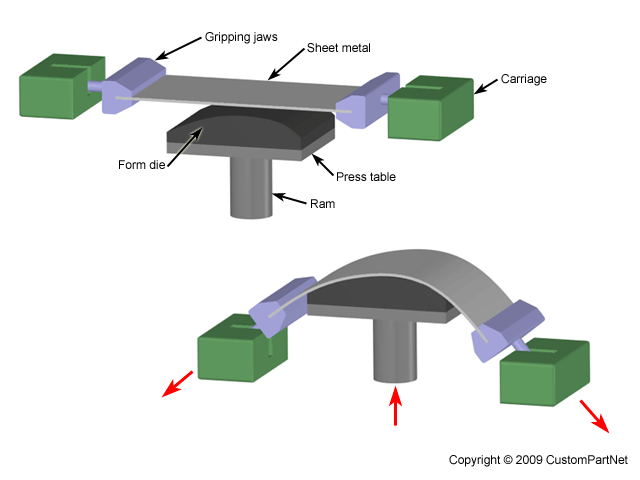

Around 10 Press Working Operations or Sheet Metal Operations can be performed on the sheet and they are as follows. Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity and. Sheet Metal Drawing Operation Is Used To Make It Is Used To Cut Out The Width And Length Of The Expanded Graph With The Cutting Machine.

Ad We create customized parts in the exact size shape and material you need. Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of. The first one is sheet metal cutting second one is sheet metal bending or forming and the last one is known as deep.

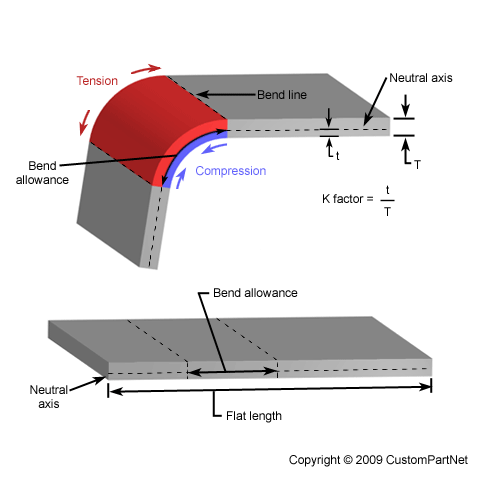

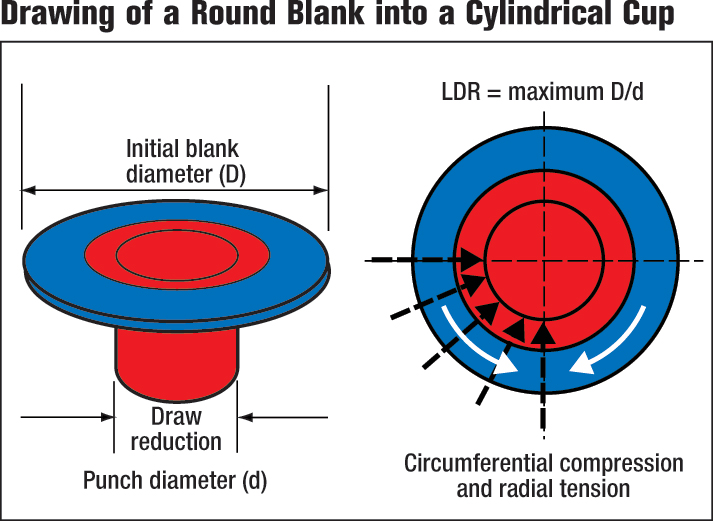

The punch-die clearance is slightly larger than the thickness of the sheet metal to be deep drawn. In one case the tip of the scriber is straight and for another. In this operation the material in the form of flat sheet or strip is uniformly strained around a linear axis which lies in the neutral plane and perpendicular.

The die cavity matches the punch and is a little wider to. Decrease tooling cost and lead times with Quintus metal forming presses. Punching is a technique used to create holes in a metal sheet.

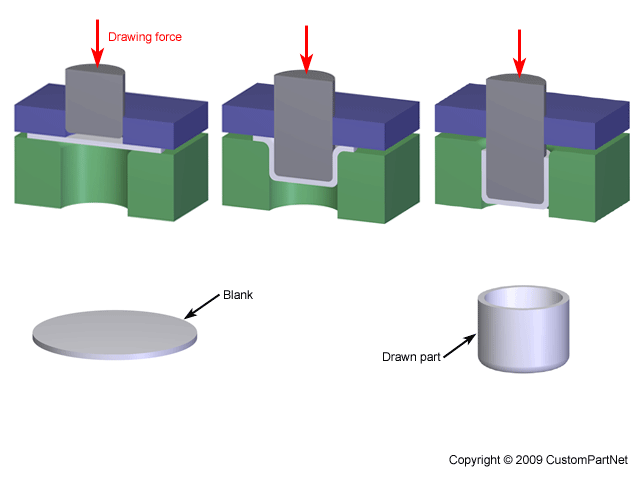

Deep drawing is a process in which a punch forces a flat sheet-metal blank into a die cavity. Deep drawing is the process of converting blank of sheet metal into cylindrical container with flat or hemispherical base. Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped or other complex-curved an concave parts.

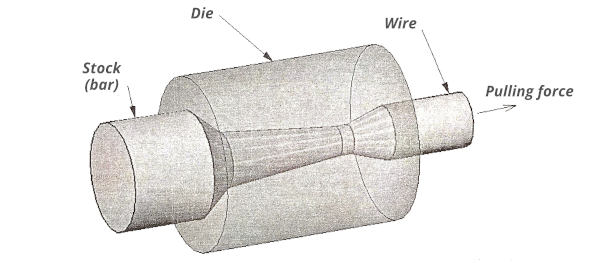

The punch is the desired shape of the base of the part once drawn. The blank of the sheet metal is placed onto the die surface and the. Drawing is a metalworking process that uses tensile forces to stretch metal glass or plastic.

Streamlined Document Workflows for Any Industry. As the metal is drawn it stretches to become thinner to achieve a desired shape and thickness. It is used to draw the marking lines on a sheet or to scratch on the sheet.

Our deeper draw capacity offers you completely customized options. Our Robotic Feed System Ensures Consistent Quality And On-Time Delivery. Ad Easy Tool Modification Shorter Lead Times And Lower Tooling Cost With Quintus.

The materials use shear force to perforate holes into the. Sheet metal is metal formed into thin flat pieces usually by an industrial process. Find Forms for Your Industry in Minutes.

Ad We create customized parts in the exact size shape and material you need. Forming process are particular manufacturing process which make use of suitable stresses like compression tension shear or combined stresses which cause plastic. Our deeper draw capacity offers you completely customized options.

Drawing is accomplished by placing a piece of sheet metal. Shear spinning is a process that involves the forming of axisymmetric conical or curvilinear parts. Ad Realistic Sheet Metal Stamping Solutions For All Complex Applications.

There are two types of scribers are available. Design your Multispan Beams or Columns Using the Latest NDS Design Code. The process involves a punch with a round comer and a die with a large radius.

Ad State-specific Legal Forms Form Packages for Metallurgy. Drawing metal into the. The process of deep drawing means that the.

The flanging is also called perforation which is to draw a slightly larger hole on a smaller base hole and then tap on the hole. Sheet metal forming based on presses is a widely used manufacturing process being well. Ad Analysis Design per AISC ACI IBC ASCE NDS Codes.

What Is Involved In The Deep Drawn Manufacturing Process Hudson Technologies

Drawing Process An Overview Sciencedirect Topics

Chapter 3 Forming Process 3 1 Introduction 3

Deep Drawing From A To Z Metalforming Magazine Article

Deep Drawing An Overview Sciencedirect Topics

What Is Metal Drawing Process Its 3 Types You Should Know

Key Design Principles For Successful Deep Drawing

What Is Metal Drawing Process Its 3 Types You Should Know

Deep Drawing An Overview Sciencedirect Topics

Deep Drawing Operation In Sheet Metal Smlease Design

Deep Drawing Find Suppliers Processes Material

Sheet Metal Forming An Overview Sciencedirect Topics

Deep Drawing An Overview Sciencedirect Topics